OFFICINA TELAI

We Develop great Frames for real Bike Lovers.

Frameworkshop… Everything started before the II W W when Silvio Billato , my father , begin to work in a bicycle frame factory in Padova to learn the “mestiere” from the old and skilled workers , during the war , cause the workers were called to the army , the young man became worker producingframes and made experience how to improve the production. After the end of the war and after some experience as motorcycle mechanic that was profitable to prepare the track speciality “dietro motori” in Padova Velodromo Monti when he took care of the local team .back to produce frames in other factory in Padova in 1954 with other 4 workers decided to open their own workshop to produce frames and forks for the local bicycle factories.

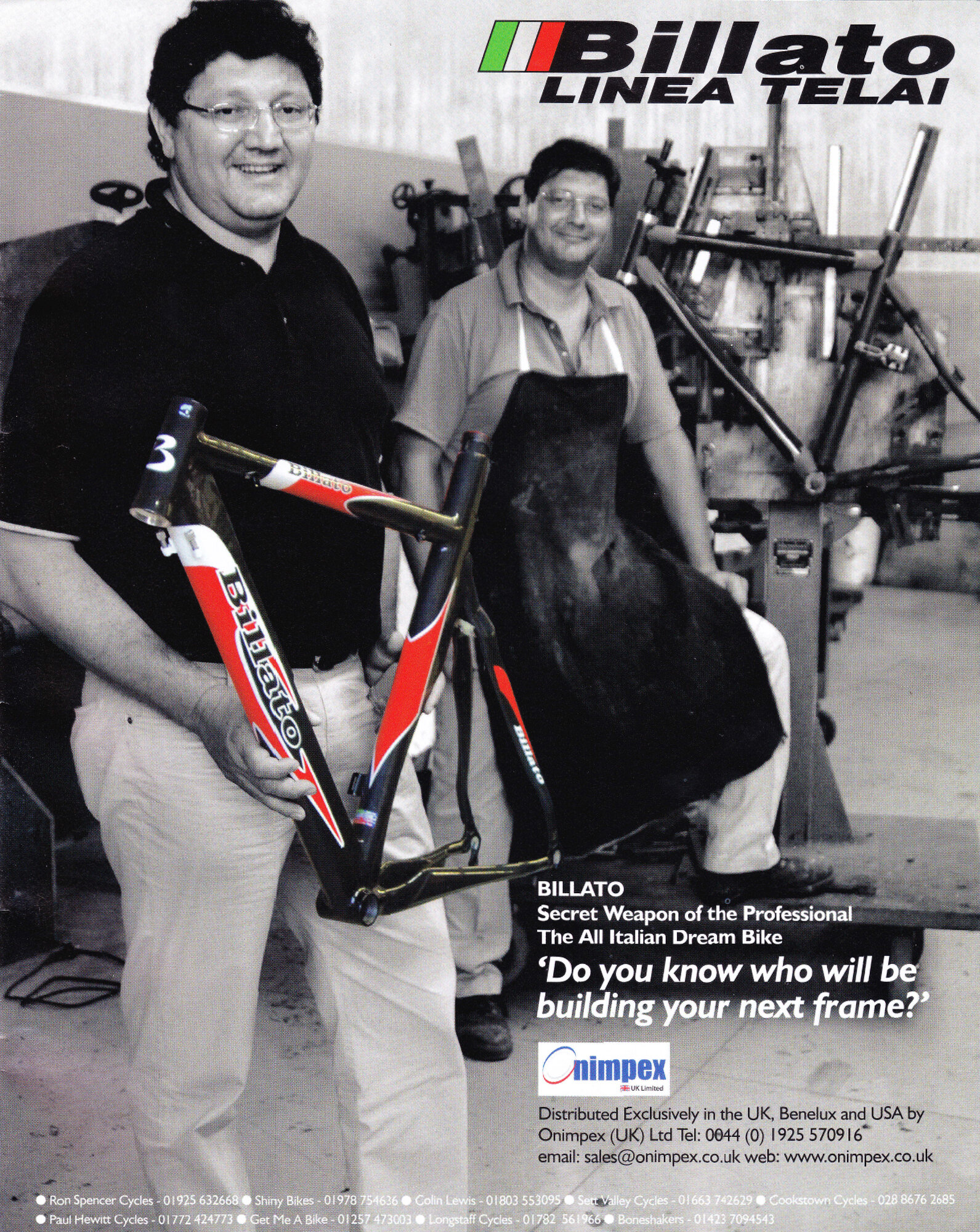

In 1962 my father and his friend Meneghello Guerrino started with Meneghello & Billato sdf with the mission to produce high quality frames for the market. A parallel production of road professional frames started with prestigious brands like Vicini, Legnano, Coppi, Boeris, Bianchi, Scapin, Ganna, Piave, Berma, and other names no more in the market.

In 1978 I join to the workshop to help them and after some months I looked to expand the production to other markets changing the classical position of handcrafted framebuilder to a proposal and innovative framebuilder with different view and open to the evolution of the materials. Some more new international customers like Detto Pietro , Alan Looyd, Butler , Brewo, Bikecology USA , Cicli Masi Inc. USA, Ten Speed Drive USA, Nichinao Sochai-JPN, IKO-DE, Le Taureau-DE, and others. The introduction of Columbus MS and Max as well as the oversize Nivacrom and the TIG welding with Excel Kevlar reinforced superlight tubing made big step for our production.

The international market looked at our production as well as big companies like Concorde- Marin- Greg LeMond, Look, Fondriest gave us the production of their team custom frames also with the innovative ( for that time ) aluminium as Scandium and Deda SC61.

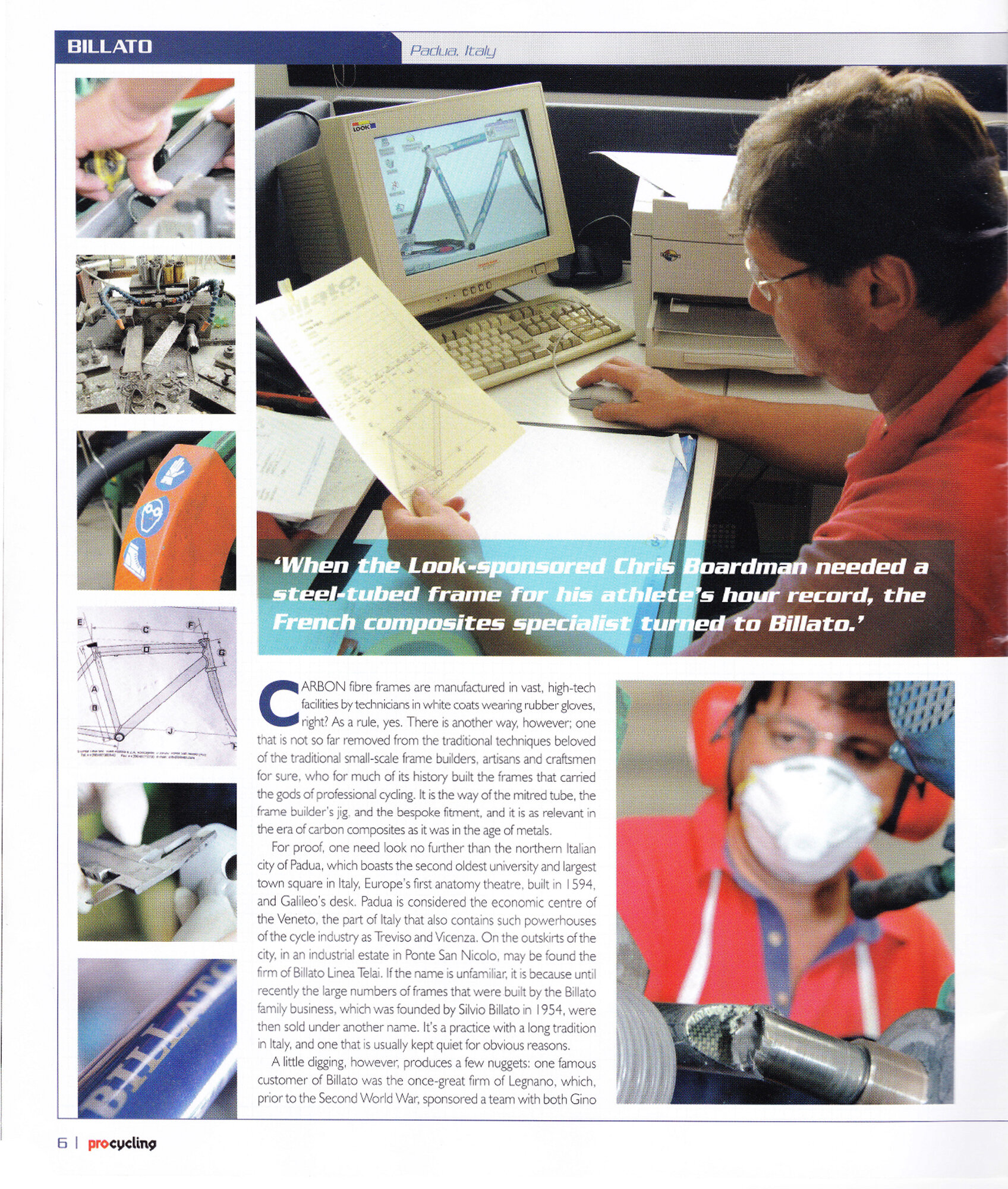

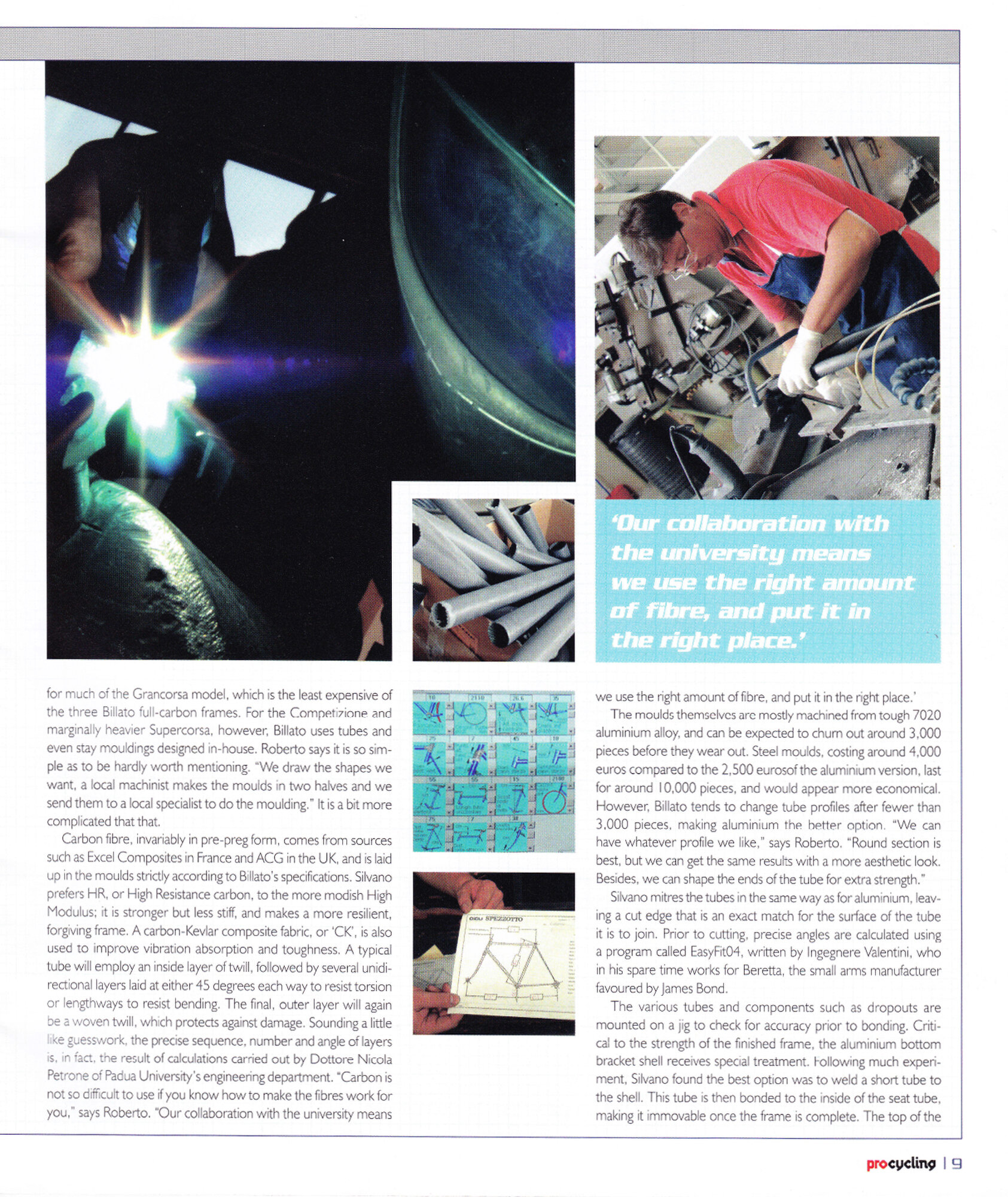

The natural evolution of the product came to the best material for a framebuilder at the end of 90’s with the first test with carbon fiber tubing (from Look KX) using a tech process that permitted to remain framebuilder , so made custom building frames:

CWS acronym of Carbon Wrapped System that permit to build a custom size frame also with carbon fiber not only with metal tubing.

Isn’t a easy operation and have to make with expertise workers under the strict control of skills engineers.

But the result is really the best performance from a bicycle professional frame never had , the possibility to create and to modify in every joint the structure of the frame is absolutely amazing.

Re-created the skill of “telaista” with different materials: from steel (first love) to composite carbon fiber going trough the Titanium paying attention to all the small details so important to obtain the satisfaction of the athletes riding a BILLATO.